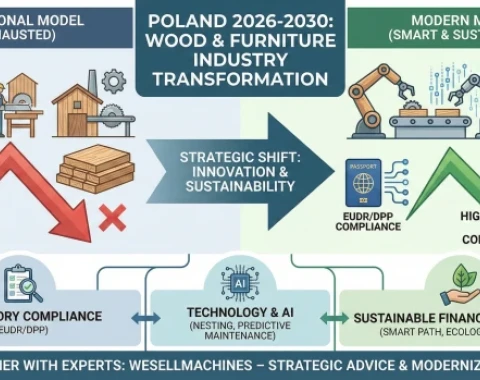

The End of the "Cheap Furniture" Era? Your Survival and Growth Strategy for 2026–2030

2025-12-04

The End of the "Cheap Furniture" Era? Your Survival and Growth Strategy for 2026–2030

Author: Marcin Białczyk | Expert in Heavy Industry Machinery & Modernization

For decades, the Polish wood and furniture industry has been the undisputed leader in exports, generating an impressive €16.3 billion in 2024. We were the "furniture factory for Europe," winning on price, raw material availability, and skilled labor. However, as a practitioner who visits your plants daily, I see it clearly: this model is running out of steam.

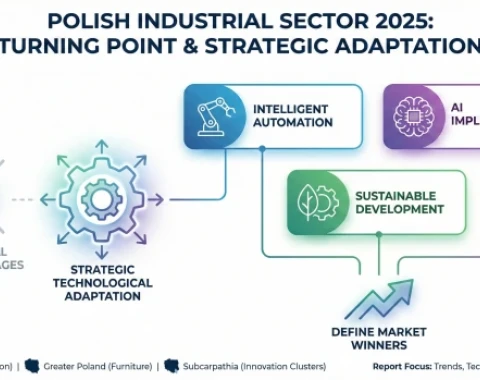

We are facing a "perfect storm." Rising labor costs, regulatory pressure from Brussels, and sleepless competition mean that simple competitive advantages are no longer enough. In the years 2025–2030, the winners won't be those who cut the cheapest, but those who cut the smartest.

In today’s article, based on hard market data, I will show you how to turn upcoming regulations (EUDR, ESPR) into an advantage and why modernizing your current machinery park might be a better decision than buying new equipment.

1. Regulatory Tsunami: EUDR is Just the Beginning

Many of you ask me about the EUDR (European Union Deforestation Regulation). Although implementation deadlines have shifted (end of 2025 for large companies, mid-2026 for SMEs), treating this as a "holiday from regulations" is a strategic error.

EUDR marks the end of anonymous raw materials. Every board, every chipboard must have its digital geolocation history. But that's not all. On the horizon, we can already see the Digital Product Passport (DPP). From around 2027, furniture without a "digital twin"—containing data on carbon footprint and materials—may be blocked from the EU market.

What does this mean for your machines?

Traditional "paperwork" is becoming obsolete. Your machines—from sawmills to CNC centers—must become part of a digital ecosystem.

-

Integration: A modern production line must "know" what it is processing and automatically report it to the ERP system.

-

Identification: The necessity to implement marking systems (QR codes, RFID) integrated directly into the machining process.

Expert Tip: When investing in machinery, ask not just about mechanical output, but about Digital Connectivity. A machine that doesn't generate data becomes a "blind link" in the supply chain.

2. Artificial Intelligence on the Factory Floor – It’s Not Sci-Fi

Let's forget about AI generating images for a moment. The real revolution is happening in nesting optimization. In a traditional plant, material waste often reaches 20-30%. That is money thrown into the waste bin.

Industrial AI changes the rules of the game:

-

Machine Vision: Scanners analyze wood defects in real-time.

-

Learning Algorithms: The system plans the cut to maximize material yield, learning from thousands of previous operations.

Thanks to this, vision systems achieve a defect detection rate of 99.9%. This is not just raw material savings, but primarily the avoidance of costly complaints about the finished product.

3. Retrofitting: A Second Life for Your Machines

As a machinery valuation expert, I often face the dilemma: buy new or modernize the old? In these times of expensive financing, retrofitting is becoming the number one option.

Why is it worth it?

-

Economics: The cost of modernization is a fraction of the price of a new machine, yet it extends its life by 10–15 years.

-

Time: You avoid long waiting times for new equipment delivery.

-

Efficiency: Replacing controls and drives can increase the efficiency of an old machine body by 10–30%.

A Note on Safety:

Modernization is not just about replacing a PLC. Under the new EU Machinery Regulation, deep interference can legally make you the "manufacturer" of the machine. At WeSellMachines, we place immense emphasis on ensuring every retrofit goes hand in hand with adapting to Health & Safety requirements (guards, emergency stops), which is currently a prime target for labor inspections.

4. Don't Let Machines Stop: Predictive Maintenance

A spindle failure at the peak of the season is every production manager's nightmare. We are moving from a "fix it when it breaks" model to Predictive Maintenance.

Modern diagnostics include:

Shutterstock

-

Vibration Analysis: Detects bearing damage before it becomes audible to the ear.

-

Current Analysis: VFD errors (e.g., Overcurrent OC1) often signal winding or mechanical problems long before a critical failure.

5. How to Finance the Change? Investment Roadmap 2025–2026

Even the best technology requires a budget. Fortunately, the years 2025–2026 offer a wide range of support instruments in Poland. Here is a summary of the most interesting financial tools available to our clients:

| Financial Instrument | Target Group | What can funds be used for? | Benefit |

| SMART Path (FENG) | SMEs & Large Firms | Innovation, digitalization, greening | Grant up to 80% (depending on region) |

| Robotization Relief | All (PIT/CIT payers) | Industrial robots and peripherals | Deduct 50% of costs from the tax base |

| BGK Ecological Credit | SMEs | Machine modernization (energy savings >30%) | "Green premium" paying off part of the loan |

| ZUS Grants for Safety | Social Security Payers | Dust extraction, machine guards, noise reduction | Non-repayable grant for improving working conditions |

Summary: Partnership Instead of Just Sales

The market is changing, and we are changing with it. At WeSellMachines, we don't want to be just a supplier of "hardware." We understand that today you need a partner who will help you navigate the maze of regulations, select technology for specific EUDR requirements, and help optimize energy consumption in your plant.

The future of the industry lies in quality, data, and efficiency. Machines are just tools, but properly selected, they become the foundation of success.

What can I do for you?

Is your production hall ready for the challenges of 2025? Contact me directly. Let's analyze your machinery park regarding modernization potential, energy savings, and compliance with new safety standards.

Marcin Białczyk

Your partner in the world of heavy industry

Content added:

Marcin Białczyk

Marcin Białczyk

Log in with Facebook

Log in with Facebook Log in with Google

Log in with Google