Ads Professional packaging lines and end-of-line systems from Mojusz

Horizon StitchLiner 5500 (2006) saddle stitching line

Added: 03.12.2025, 22:57

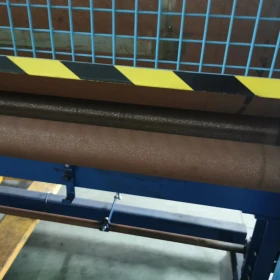

ROLLER ZMMbp-2000 Slitter-Scorer Urgent

Added: 13.11.2025, 21:07

USED IGP GENIUS 900 Laminating Machine Urgent

Added: 13.11.2025, 20:56

Duplo DC-445 DuCreaser automatic creaser Urgent

Added: 13.10.2025, 13:30

Heidelberg GTO 52-4 P3 Machine Urgent

Added: 10.10.2025, 10:37

CTP Platesetter Fuji Film LUXEL T-6500S (2017) Urgent

Added: 08.10.2025, 11:14

Used Offset Press SHINOHARA 74-4 (2008) Urgent

Added: 08.10.2025, 10:35

EFFICIENT AND RELIABLE UV DRYER TUNNEL 2006 – Near-New Technical Condition! Urgent

Added: 07.10.2025, 16:51

Semi-Automatic Screen Printing Machine A3/A4 Urgent

Added: 07.10.2025, 16:42

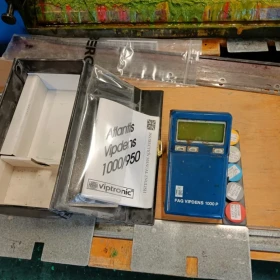

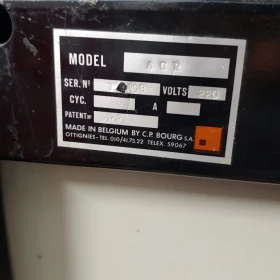

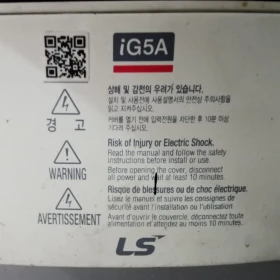

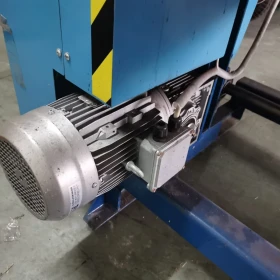

Bourg Collating and Bookleting Line BST-24 / AGR-T / PA-T - An Investment in Reliability

Added: 07.10.2025, 16:31

FMB 1-Color Flexographic Printer | 2300 mm Width | Like New Condition Urgent

Added: 24.09.2025, 20:26

Maszyna 5-segmentowa Langston - do Druku i Wycinania Opakowań Urgent

Added: 19.12.2024, 11:51

Packaging Automation - Complete Solutions from Product to Pallet

We offer a wide portfolio of used packaging machines: horizontal and vertical flow packs, vacuum machines, carton erectors, dosing systems, wrappers, and palletizers. We collaborate with leaders: Bosch, Multivac, Ulma, CAM, KUKA, Marchesini. Each machine undergoes a 175-point inspection including packaging leak tests, dosing calibration, safety system verification, and Track&Trace validation. Savings range from 45-60% while maintaining OEE efficiency >75% and packaging quality >99.5%.

Critical Parameters Verified Before Sale

We check the sealing integrity (burst test >30 kPa), dosing accuracy (±0.5% or ±1g), synchronization of mechanisms (±2ms), coding quality (Grade A according to ISO 15415), cleanliness for food-grade (ATP <100 RLU), serialization readiness (Level 2-4), actual vs nominal performance (>85%), and stability of process parameters (Cpk >1.33).

Key Packaging Machines:

Horizontal Flow Packs: Bosch Pack 301, Ulma Artic, Ilapak Carrera. 30-300 packs/min, MAP/skin, film width up to 680mm.

Vacuum Machines: Multivac R245, T300, VC999. Thermoforming and tray sealer, medical grade, MAP up to 5 mbar.

Carton Erectors: CAM AV, Marchesini MA, Romaco Promatic. 50-300 cartons/min, serialization ready, leaflet insertion.

Palletizers: KUKA KR 180-700, ABB IRB 660, Fanuc M-410. Up to 2500 cycles/h, multi-SKU, layer forming.

Advanced FAQ - Validation and Optimization of Packaging Systems

How to Conduct Qualification of Bosch Pack 301 Flow Pack for Food Products with MAP?

Basic mechanical qualification: Sealing jaws: Long dwell seal bar 400mm. Temperature: uniformity ±2°C over length (8 measurement points). Teflon coating: thickness >20μm, cross-cut adhesion test = 0. Pressure: pneumatic 4-6 bar, uniform ±0.5 bar. Sealing time: 0.3-0.8s adjustable every 0.05s. Synchronization: box-motion cam, phase ±0.5°. Product feeding system: Chain: pitch 125mm, play <0.5mm. Pushers: synchronization ±2mm, soft for delicate items. Photoeye: response <0.5ms, contrast >1.5% @ 200 ppm. Reject: pneumatic, response time <100ms. Film guiding: Unwinder: diameter up to 600mm, magnetic brake. Tension: dancer roller 10-30N adjustable. Tracking: ±1mm over 6m length, edge photoeye. Coding: data/lot inline, OCR verification optional. MAP (Modified Atmosphere Packaging) system: Gas mixer: Witt KM100-3 or similar. Accuracy: ±1% for each gas (N₂, CO₂, O₂). Flow: 50-200 l/min depending on speed. Monitoring: continuous residual O₂, alarm <1%. Gas flush: Nozzles: 6-8 pieces across product width. Volume exchange: 3× package volume. Residual O₂: <1% for meat, <3% for bread. Leak test: every 30 min, blue dye penetration. Sealing parameters (OPP/PE 40μm): Jaw temperature: Upper: 140-150°C. Lower: 135-145°C. Final transverse: 145-155°C. Longitudinal: 130-140°C continuous seal wheels. Seal quality: Width: 8-10mm nominal. Strength: >25 N/15mm (peel test ASTM F88). Integrity: burst test >30 kPa. Aesthetics: no wrinkles, discoloration, channels. Process validation (IQ/OQ/PQ): IQ - Installation Qualification: Utilities: 3×400V 32A, compressed air 6 bar. Space: 6×3m, height 2.5m, 360° access. Leveling: <0.1mm/m, vibration isolation. Documentation: schematics, CE certificates, instructions. OQ - Operational Qualification: Speed range: 30-200 ppm verification. Format range: 50×30 to 300×200mm. Temperature: all zones ±2°C stability. Gas mixing: ±1% composition accuracy. Alarms: all active, E-stop <0.5s. PQ - Performance Qualification: Test product: sausage 200g in MAP. Batches: 3×1000 packages. Format: 180×220mm, MAP 70/30 N₂/CO₂. Seal integrity: 100% test of the first 100. Residual O₂: <1% average, max 1.5%. Dimensions: ±2mm length, ±1mm width. Gas weight: ±5% target (volume compensation). Bosch MEC control system: Recipe management: 100+ products in memory. Format change: <15 min with tools, <5 min without. Production data: OEE real-time, quality stats. Maintenance: predictive alerts, spare parts. Integration: MES Level 2-3, OPC-UA protocol. Production efficiency: Nominal: 200 ppm for simple packages. Actual: 170-180 ppm (85-90% availability). MAP impact: -20% speed vs standard. Multi-pack: -40% for 2×3 configurations. Film usage: >92% (width 400mm, product 180mm). HACCP/GMP documentation: SOP: setup, production, cleaning, format change. CCP: sealing temperature, gas composition, metal detection. Validation: microbiological post-CIP, ATP <100 RLU. Training records: certified operators. Batch records: full traceability of raw materials. Operating costs: Film: 0.08-0.12 EUR/package. Gas: 0.02-0.03 EUR/package MAP. Energy: 8-12 kW average consumption. Parts: jaws 2000 EUR/year, Teflon 500 EUR/year. Service: 2000-3000 EUR/year preventive.

Comprehensive Support in Packaging Automation

We offer a full range of services: line audit with OEE optimization, installation with integration into existing systems, validation for pharmaceuticals and food (IQ/OQ/PQ), implementation of serialization and Track&Trace, training for operators and mechanics, preventive service with predictive diagnostics. We provide spare parts, films and tapes, vision and coding systems, upgrades (servo, robots, IoT). Support for certification (FDA, CE, ISO). Financing: operational leasing, rental, trade-in. Contact for TCO analysis and end-to-end automation proposals.

Log in with Facebook

Log in with Facebook Log in with Google

Log in with Google