Ads Professional machines for paper, cardboard, and film from Zielona Góra

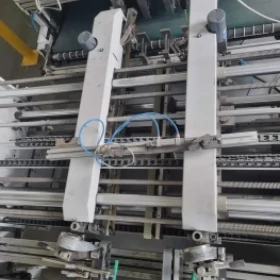

VERSO SERTO 160 K4 folder gluer

Added: 19.02.2025, 11:42

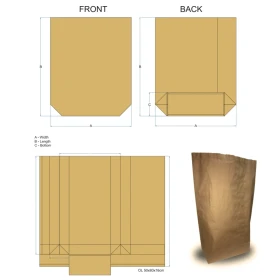

BODEN LEGER Machine for Valve and Bottom Bag Production, EUR 70000 EXW Urgent

Added: 09.01.2025, 17:07

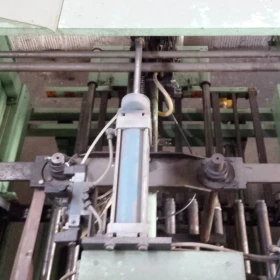

PINCH BOTTOMER Machine, ICOMA Packtechnik, 1982, Modernized, EUR 18000 EXW Urgent

Added: 09.01.2025, 15:24

Boxmat 2400 Cardboard Box Production Machine, Zemat Technology, Used, 14000 EUR EXW Urgent

Added: 09.01.2025, 13:39

Technological line for the production of corrugated cardboard, model WJ150-1600-3, and a cardboard drying line Urgent

Added: 04.12.2024, 14:20

Comprehensive solutions for the paper and packaging industry

We offer a wide range of used machines for paper, cardboard, and film processing: rotary and flat die-cutters, folder-gluers, laminating machines, programmable guillotines, quality inspection systems. We collaborate with leaders: Bobst, Heidelberg, Polar, Komori, Diana. Each machine undergoes a 145-point inspection including mechanical tests, calibration of positioning systems, verification of die-cutting and creasing quality. Savings when purchasing used machines range from 45-65% while maintaining production efficiency >85% of new machines.

Technical parameters verified before sale

We check the synchronization of the upper and lower die-cutter plates (±0.05mm at full speed), uniformity of pressure (300±20 tons across the surface), condition of cutting tools (knife height 23.8±0.1mm), precision of sheet feeding systems (±0.5mm positioning), quality of creasing and perforation, efficiency of waste removal systems, calibration of guillotines (accuracy ±0.1mm over a length of 1000mm).

Key machines in the offer:

Die-cutters: Bobst SP 102/104/142, Heidelberg Varimatrix. Formats B1-B0, speeds up to 9000 sheets/h, automatic waste removal, hot foil application.

Folder-gluers: Bobst Domino, Expertfold, Kama ProFold. Widths 50-110cm, speeds up to 450m/min, gluing 4/6 points, automatic bottom.

Guillotines: Polar 115/137/176, Wohlenberg. Cutting programming, accuracy ±0.1mm, automatic feeding systems.

Laminators: Komfi, GMP, Autobond. Thermal and wet, formats B1+, speeds up to 100m/min, UV and soft-touch.

Advanced FAQ - Diagnostics and process optimization

How to conduct a comprehensive diagnostic of the Bobst SP 102-E die-cutter with tool condition assessment?

Mechanical inspection of main components: Plate synchronization: check upper and lower plate ±0.05mm at 7500 sheets/h. Bearing play measurement of the main shaft: <0.02mm with a dial gauge. Vibrations: <3mm/s RMS at 125 cycles/min maximum speed. Die-cutting pressure test: uniformity 300±20 tons across the entire surface. 4-point adjustment: correction capability ±0.1mm at corners. Plate parallelism: <0.03mm/1000mm (laser or precision ruler). Sheet feeding system: Vacuum belts: tension 120±10N, minimum vacuum -0.6 bar. Positioning accuracy: ±0.5mm repeatability on marks. Grippers: all 16 operational, gripping force 30-50N each. Opening synchronization: <5ms between outer grippers. Hot foil application station (if equipped): Temperature: 140±5°C stability across the entire width. Pressure time: 0.3-0.8s adjustable depending on the foil. Release force: >200g/15mm for good adhesion. Registration: ±0.2mm foil positioning accuracy. Waste removal station: Upper/lower needles: alignment <0.2mm across the entire width. Removal tools: no cracks, penetration test. Synchronization: pushers operate in phase with the sheet. Effectiveness: >99% removal with proper setup. Separation station: Separation precision: ±0.3mm between products. Pusher synchronization: <10ms delay. Stacking: jogger operational, stack evenness ±5mm. Condition of cutting tools: Knife height: 23.8mm new, minimum 23.6mm for operation. Sharpness: no chips >0.1mm, paper cutting test 80g. Creasers: width 0.7-2.0mm, depth as per specifications. Die: surface without dents >0.2mm, pertinax strips <50% worn. Tool preparation: time 15-20min for repeatable orders. Registration: ±0.2mm accuracy relative to print. Production test: Test material: cardboard 350g/m², format 72×102cm. Speed: 7000 sheets/h steadily for 30 minutes. Die-cutting quality: clean edges, no fiber tears. Dimensional accuracy: ±0.3mm on external dimensions. Creasing: uniform, no cracks when folding 180°. Efficiency: utilization >85% on batch orders. Electronics and control: Siemens S7 PLC: all inputs/outputs active. Encoders: absolute, resolution 0.01mm. HMI panel: all functions available, 50+ programs saved. Safety sensors: operational light barriers. Documentation and data: Makeready instructions: 200+ standard formats. Die-cutting programs: USB save and read capability. Counters: production, waste, operating time. Maintenance history: available for the last 24 months. Expected operating costs: New tools: 2000-5000 EUR depending on complexity. Replaceable knives: 500-800 EUR/set every 500k cycles. Main service: 15000 EUR every 5 million cycles. Consumables: 200-300 EUR/month on average.

Log in with Facebook

Log in with Facebook Log in with Google

Log in with Google