Used Plastic Processing Machinery

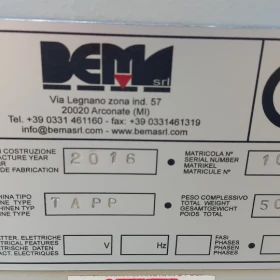

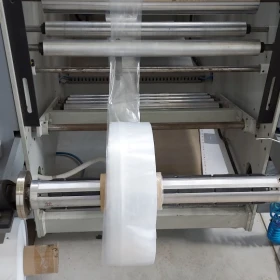

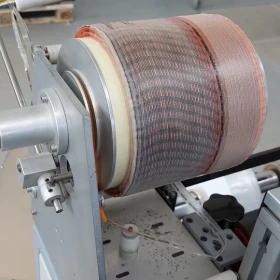

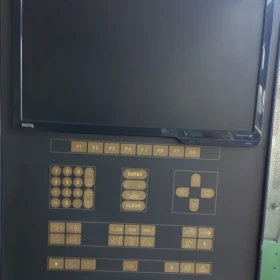

BEMA SLR TAPP

Added: 09.05.2023, 19:52

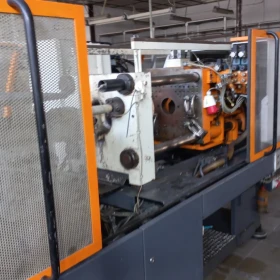

带EC90控制的恩格尔80T注塑机

Added: 09.05.2023, 19:50

挤出机 GMFR100K L+J Industrie Elektronik gmbh 制造于1987年

Added: 09.05.2023, 19:50

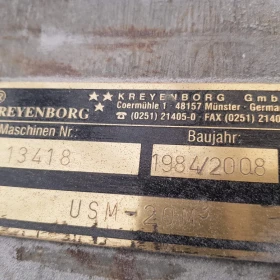

Kreyenborg筒仓混合机 制造于1984/2008年

Added: 09.05.2023, 19:50

INFRAFORM TFSXS 2020

Added: 24.04.2023, 15:53

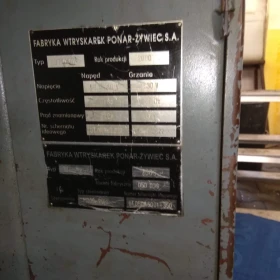

注塑机 PONAR ŻYWIEC UT 050.H 生产年份:2000

Added: 19.04.2023, 12:32

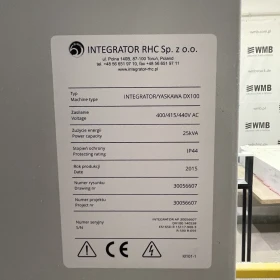

安川Motoman ES165D + 转台 + 8.5 kW主轴 + 带吊坠的控制柜 生产年份:2015

Added: 11.04.2023, 14:00

Explore our comprehensive inventory of second-hand plastic processing machinery. This category includes injection molding machines, extruders, blow molding machines, thermoformers, and granulators for all types of plastic manufacturing. Find reliable equipment from leading brands like Arburg, Engel, and KraussMaffei.

Key Purchasing Considerations for Used Plastic Machinery

- Machine Type and Tonnage/Size: Ensure the machine (e.g., injection molder clamping force in tons, extruder screw diameter in mm) is correctly sized for your products and molds.

- Screw and Barrel Condition: For extruders and injection molding machines, the condition of the screw and barrel is critical and expensive to replace. Inquire about wear measurements if available.

- Operating Hours: The number of hours the machine has been in operation is a key indicator of its overall condition and remaining lifespan, especially for the hydraulic system.

Frequently Asked Questions About Plastic Machinery

What is the difference between injection molding and blow molding?

Injection molding involves injecting molten plastic into a closed mold to create solid parts. Blow molding is a process used to create hollow plastic parts, like bottles, where a heated plastic tube (parison) is inflated into a mold cavity.

What does the clamping force of an injection molding machine mean?

Clamping force, measured in tons, is the force that the machine uses to hold the two halves of the mold closed during the injection process. The required clamping force depends on the size of the part and the pressure of the injected plastic. Insufficient clamping force will result in the mold being pushed open, causing defects like "flash".

使用以下方式登录 Facebook

使用以下方式登录 Facebook 使用以下方式登录 Google

使用以下方式登录 Google