How to Choose a Used Wood CNC Machining Center? A Complete Machine Audit Step-by-Step

2025-10-30

Chapter 1: The Homework – Before You Schedule an Inspection

Buying "just any" CNC is a recipe for disaster. You must buy the right CNC, matched to your production profile.

1.1. Define Your Mission: Key Parameters

You must know what you're looking for.

- Table Type (The Key Decision):

- Flat Table (Nesting): A machine with a flat vacuum table, often with an MDF "spoilboard". Ideal for nesting—cutting full sheets of particleboard, MDF, or plywood. This is the machine for cabinet and case good manufacturers.

- Pod and Rail Table (Console / Beam): A machine where the part is held on special consoles (beams) using vacuum pods (cups). This allows for 5-sided machining (e.g., horizontal drilling, edge processing). Ideal for manufacturers of fronts, doors, windows, chairs, and solid wood components.

- Working Area (X, Y, Z):

- X, Y: What is the largest panel or part you will process? A market standard is often around 3050x1530 mm or larger.

- Z-Axis (Clearance): How tall are the parts you will machine? Standard clearance (e.g., 150-200 mm) is fine for panels, but for machining molds, models, or solid wood parts, you'll need much more.

- Number of Axes:

- 3-Axis: Standard for nesting, milling, and drilling.

- 4-Axis: An additional "C" rotational axis on the spindle, allowing the use of aggregates (e.g., a grooving saw, horizontal drill). Vastly increases flexibility.

- 5-Axis: Full control over the tool's angle. These are machines for complex 3D machining, molds, models, and chair components. They are the most expensive and complex to program.

1.2. Preliminary Interview with the Seller

Ask precise questions so you don't waste time on a trip:

- "May I have the exact model, year of manufacture, and control model?" (e.g., Homag WoodWOP, Biesse BiesseWorks, SCM Xilog).

- "How many hours has the spindle run, and how many hours has the machine been powered on?" (Spindle hours are the real indicator of wear).

- "What materials were primarily machined on it?" (MDF/particleboard is extremely abrasive. Solid wood is less so).

- "Is the machine under power, functional, and can it be tested under load?" (If not, the risk increases dramatically).

- "Have the spindle or vacuum pump ever been replaced or refurbished? If so, I'd like to see the documentation."

Chapter 2: The Heart of the Machine – The Spindle (Electrospindle) Audit

This is the single most important, most expensive, and most wear-sensitive component of a CNC center. A spindle failure means downtime and a repair cost in the thousands or tens of thousands.

2.1. Spindle Specifications

- Power (kW): Must be matched to the job. 8-10 kW is sufficient for nesting particleboard. For heavy solid wood machining or stacked panels, 12-15 kW or more is needed.

- Cooling:

- Air-Cooled: Simpler, cheaper, but louder. Sensitive to ambient dust.

- Liquid-Cooled (Water/Glycol): Quieter, more stable operating temperature. Requires an external chiller unit. Check the chiller—is it working, are there leaks, is it clean?

- Tool Holding System:

- HSK-63F: The market standard in woodworking machines. Provides excellent rigidity and precision.

- ISO-30: A lighter system, popular in smaller machines.

2.2. Physical Inspection (Machine OFF)

- Spindle Taper: Ask to have the tool holder removed. Using a clean cloth and a flashlight, carefully inspect the internal taper of the spindle. Look for rust, pitting, scratches, or signs of "fretting" (a rusty-looking deposit). Any blemish on this surface means problems with precision and bearing life.

- Tool Clamping System: Check that the mechanism (usually pneumatic) works smoothly.

- Runout Test (Advanced): If you have a dial indicator with a precision test bar, mount it and check the runout on the taper and at the end of the test bar. Any value over 0.01-0.02 mm (0.0004" - 0.0008") on the taper is alarming.

2.3. Functional Test (Machine ON)

- Cold Start: Start the spindle at low RPM (e.g., 6000 RPM). Listen. You should only hear a quiet hum from the motor and air. Any knocking, grinding, "crunching," or loud whining indicates worn bearings.

- Warm-up Program: Professional machines have a spindle warm-up cycle. Ask to run it. The machine should smoothly increase RPM every few minutes. Listen at each stage.

- Max RPM Test: Run the spindle at maximum RPM (e.g., 18,000 or 24,000 RPM) with no load for a few minutes. The sound must be consistent, smooth, and free of vibration.

- Temperature Test: After a few minutes at high RPM, stop the spindle and carefully touch its housing. It should be warm, but not hot. Excessive heat = bearing or cooling problems.

- Load Test: This will be covered in Chapter 6.

Chapter 3: The Foundation – The Table and Vacuum System

Without solid, leak-free material clamping, all the CNC's precision is worthless.

3.1. Flat Table (Nesting)

- Spoilboard: This is a consumable item (usually MDF). Check its condition. If it's heavily milled, you will need to plane it (fly-cut) or replace it.

- The Actual Table (Grid Table): Ask to have the spoilboard removed to see the main table (usually black, made of phenolic resin or aluminum). Check that it isn't cracked, deeply scratched, or damaged by a tool that cut through the spoilboard.

- Vacuum Zones: Most tables are divided into zones (e.g., 6 or 8). Ask to have each zone turned on and off from the controller. They must respond immediately.

- Pop-up Pins (Reference Pins): If the machine has them, check that all pins pneumatically raise and lower. Are any of them bent?

3.2. Pod and Rail Table (Console)

- Console/Beam Movement: Check that the consoles move smoothly on their guides. Does the locking system (usually pneumatic) hold them firmly?

- Vacuum Pods (Cups): This is a key element. Inspect the rubber gaskets on every pod. They must be soft and flexible. Hardened, cracked, or chipped rubber will not hold a vacuum. The cost to replace a full set of pods is very high.

- Positioning System: If the machine has a laser or LED indicators for positioning pods and beams, check that the system works and is accurate.

3.3. The Vacuum Pump (Lungs of the Machine)

This is the heart of the clamping system.

- Pump Type: You will most often find dry-vane pumps (e.g., Becker) or oil-flooded pumps (e.g., Busch). Dry pumps are popular, but their graphite vanes are a consumable part that must be replaced regularly.

- Location: Is the pump next to the machine (loud), or in a separate room (ideal)?

- Start and Run Test: Start the pump. Listen. Excessive knocking, grinding, or "screaming" is a bad sign.

- Suction Test: Turn on the vacuum for one zone. Place a piece of panel on it (e.g., 1x1m). Try to slide it with your hands. It should be held absolutely firm. If you can move it, the system has a leak or the pump is worn.

- Filters: Locate the main vacuum filter (usually a large canister). Ask when it was last cleaned. A neglected filter "chokes" the pump and leads to its seizure.

Chapter 4: The Brain & Nervous System – CNC Control and Electrical Cabinet

The controller determines functionality and ease of use. The electrical cabinet determines reliability.

4.1. Controller and Software

- Brand and System: (e.g., Homag WoodWOP, Biesse BiesseWorks, SCM Xilog, Fanuc, Siemens). Is it a "Windows-based" graphical system, or an old G-code-based system?

- Compatibility (CRITICAL!): This is the most important point. Ask what CAM software the shop uses (e.g., AlphaCAM, TopSolid Wood, VCarve Pro, Aspire). Do you have (or can you buy) a post-processor for your CAM that will generate correct code for this exact machine and controller model? A machine without a working post-processor is a useless piece of furniture.

- Interface: Start the controller. Check the response of the screen (if touchscreen), keyboard, and mouse. Do all buttons on the main panel and the remote pendant (JOG) work?

- Loading Programs: Check how programs are loaded. Does the USB port work? Does the network (Ethernet) connection work?

4.2. The Electrical Cabinet

- OPEN THE CABINET. The first impression is key.

- Cleanliness: The cabinet must be perfectly clean. A thick layer of wood dust in the cabinet is a mortal danger. Dust is hygroscopic (absorbs moisture), conductive, and flammable. It's a direct path to a short circuit and burning out expensive servo drives.

- Cabinet Cooling: Check the fans and filters on the cabinet. They must be clean and clear. Clogged filters = overheating electronics.

- Servo Drives: Locate the servo drives (inverters) for the X, Y, and Z axes. Are there any red "FAULT" lights on any of them?

- "Hacks" (Non-Factory Repairs): Look for hanging wires, bridged fuses, or non-original relays. This is a sign the machine had electrical problems that were "patched" with shortcuts.

Chapter 5: The Skeleton – Mechanics, Guides, and Drive Systems

These are responsible for the machine's accuracy and repeatability. Wood dust is their #1 enemy.

5.1. Frame and Gantry

- The construction must be massive, heavy, and welded. Light, bolted-together frames will vibrate during high-speed machining.

- Look for signs of a crash—cracks, dents, or signs of straightening or re-welding.

5.2. Linear Guides and Drives

- Linear Guides: Inspect all guides (X, Y, Z). They must be clean and covered with a thin film of grease. If they are dry, rusty, or (worse) covered in a resinous sludge of dust and grease, their life is near its end.

- Covers (Bellows): Check the condition of the accordion-style bellows on the guides and screws. They must be sealed. A cracked or torn bellow is an invitation for dust, which will destroy the mechanics.

- Drive System:

- Ball Screws (Usually Z-axis, sometimes Y): With the machine off, grab the spindle and try to forcefully move it up-and-down and front-to-back. Any noticeable "clunk" or play (backlash) means the screw or ball nut is worn.

- Rack and Pinion (Usually long X and Y axes): Inspect the teeth on the rack and the pinion gear on the servo motor. Look for excessive wear or chipped teeth. They must be coated in grease.

- Automatic Lubrication System: Locate the central grease pump. Is there grease in it? Is it set up and working? Ask if the machine performs a lube cycle automatically. A non-functional lubrication system is a guarantee of a quick death for the guides and drives.

Chapter 6: The "Test Drive" – Practical Tests in Material

This is the moment of truth, which verifies that all components work together. Ask to run a test program on a piece of panel.

6.1. The Test Program

If the seller doesn't have a program ready, ask them to quickly write one (or do it yourself, if you can) that:

- Cuts a large rectangle (e.g., 1500 x 1000 mm).

- Cuts a large circle (e.g., 800 mm diameter).

- Performs a series of drill holes (if it has a drill head).

6.2. What to Watch and Listen For

- During the Cut:

- Vibration: Does the machine vibrate during the cut? Does the spindle "scream" or "protest" loudly?

- Noise on Direction Change: Listen at the corners of the rectangle. Any "clunk" or "jerk" when changing direction (e.g., from X to Y) is a sign of backlash in the drives.

- Movement Smoothness: Is the motion smooth, or "jerky"?

- Dust Extraction: Is the dust collection system efficient? Is dust being effectively collected from the tool?

6.3. Inspecting the Cut Part

- Rectangle – The "Square" Test: Measure the diagonals of the cut rectangle. They MUST be perfectly equal (with a tolerance of e.g., 0.5 mm). If the diagonals differ, it means the machine is not geometrically true ("out of square")—the gantry is skewed. This is a very serious defect.

- Rectangle – Dimension Test: Measure the sides. Is the 1500x1000 mm rectangle actually that size? This tests the positioning accuracy.

- Circle – Kinematics Test: Look at the edge of the circle. Is it perfectly smooth and round? Or is it "oval-shaped" or have visible small "steps" or "flats" at the 0, 90, 180, and 270-degree points? Such defects indicate problems with backlash or servo tuning.

- Edge Quality: What is the edge quality after milling? Is it smooth, or torn out? (This is largely the tool's fault, but also spindle vibration).

Chapter 7: Peripherals – Tool Changer, Drill Head, Aggregates

These elements determine the machine's flexibility.

- Automatic Tool Changer (ATC):

- Type: Linear (on the frame or side) or Rotary (a carousel on the gantry).

- Functional Test: Ask to run a tool change cycle for every pocket in the magazine. Watch. The change must be fast, smooth, and confident. Any jamming, trouble hitting the taper, or dropping a tool is a serious problem.

- Tool Holders: How many tool holders (e.g., HSK-63F) are included? They are expensive. Inspect their condition—are they clean, or rusty and covered in resin?

- Drill Head (if present):

- Ask to test each drill bit individually (vertical and horizontal). Do they all pneumatically extend and spin?

- Aggregates (if present):

- These are special heads (e.g., a grooving saw, an angled head for horizontal drilling). Ask to see them run. These are very expensive and precise accessories.

Conclusion: The Final Calculation

You've gone through the entire audit. You have a list of potential problems. It's time to make a decision.

- The Real Price: Purchase Price + Cost of transport and installation + Cost of creating a post-processor (if you don't have one) + Cost of diagnosed repairs (e.g., replacing vanes in the vacuum pump, a new set of pods, a spindle rebuild).

- Risk Analysis: Does the sum of these costs still make this machine a bargain? Would it be better to buy a newer, more expensive, but certified machine?

Buying a used wood CNC center is a high-stakes game, but with a powerful reward. Armed with this checklist, you drastically reduce your risk and are able to make an informed, engineering-based decision.

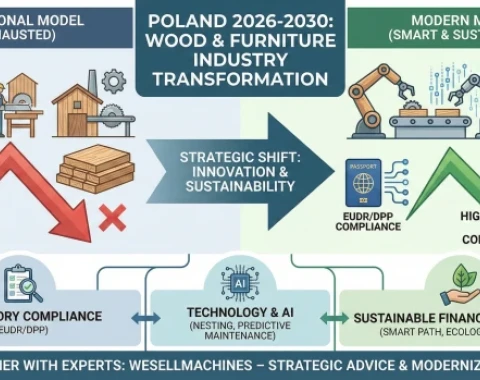

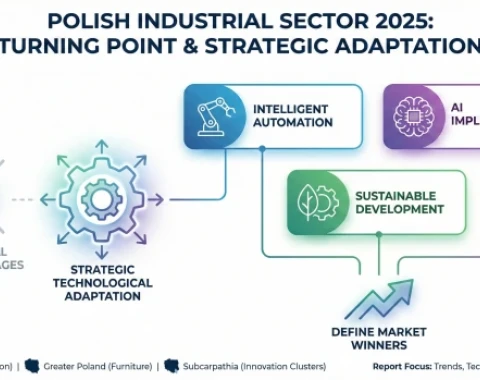

Feeling Overwhelmed? Trust the Experts.

At WeSellMachines.com, this process is our daily business. We audit dozens of machines to select only those that meet our rigorous standards.

[Link ->] See our currently available, inspected wood CNC machining centers.

Content added:

BIAŁCZYK Sp. z o.o.

BIAŁCZYK Sp. z o.o.

使用以下方式登录 Facebook

使用以下方式登录 Facebook 使用以下方式登录 Google

使用以下方式登录 Google