CNC Drilling Machining Centers for Woodworking

CNC钻铣床 Morbidelli Uniflex HP - 木工的精度和效率 Urgent

Added: 24.09.2025, 18:02

Rilesa UNI-X Save Station - 自动钻孔站 Urgent

Added: 04.03.2025, 15:18

CNC钻孔机 SCM Morbidelli Uniflex HP

Added: 03.03.2025, 15:23

多轴钻床 VITAP POINT K2 Urgent

Added: 19.02.2025, 11:40

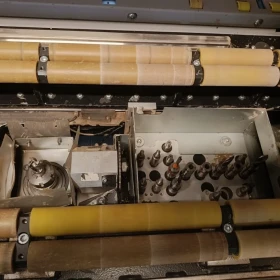

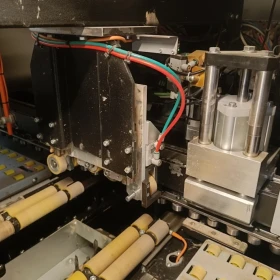

钻孔和销钉插入机 WEEKE OPTIMAT ABD 100

Added: 30.01.2023, 15:34

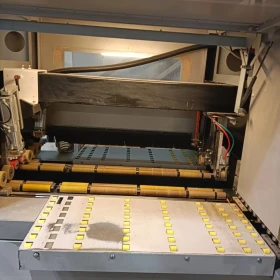

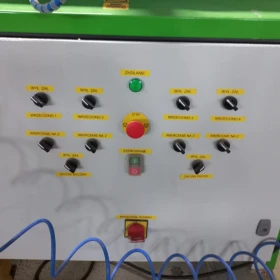

用于婴儿外套的通用模块化钻孔机 CADWIT

Added: 30.01.2023, 14:46

用于插入销钉的CNC钻孔机 VITAP BLITZ

Added: 02.08.2022, 00:00

In this section, we present advanced drilling machining centers, also known as CNC boring centers or CNC drilling machines. These are key machines in the modern furniture and woodworking industry, providing unparalleled precision, repeatability, and efficiency in drilling, routing, and grooving processes.

What are the features of CNC drilling centers?

Drilling centers are automated Computer Numerically Controlled (CNC) machines that perform complex operations on wood and wood-based panels. Unlike traditional multi-spindle drills, machining centers offer significantly more flexibility.

Key advantages of drilling centers:

- High Precision: CNC control guarantees drilling accuracy to tenths of a millimeter, which is crucial in furniture and component production.

- Automation and Efficiency: These machines minimize the need for manual intervention, speeding up production and reducing the risk of errors.

- Versatility: Many models, in addition to vertical and horizontal drilling, offer routing, grooving, or sawing capabilities, integrating several processes into one machine.

- Production Optimization: Control software allows for easy project import from CAD programs and optimization of hole patterns.

Which drilling machining center to choose?

The choice of the right model depends on the specifics of your production. When making a decision, consider the following:

- Head Configuration: The number and arrangement of drilling spindles (vertical and horizontal), and the presence of a routing spindle or grooving saw.

- Working Area: The maximum dimensions of the workpiece that the machine can handle.

- Software: Compatibility with your existing CAD/CAM systems and the user-friendliness of the interface.

- Manufacturers: Market leaders include companies like Biesse (Skipper, Eko), SCM (Morbidelli, Cyflex), Homag Group (Weeke, Brandt), and IMA, which are synonymous with quality and reliability.

Browse the listings to find a new or used CNC drilling center that will revolutionize your production process. Contact sellers to get detailed technical information and match the machine to your needs.

使用以下方式登录 Facebook

使用以下方式登录 Facebook 使用以下方式登录 Google

使用以下方式登录 Google