Crisis in the Metal Industry? It's the Perfect Time to Invest in Your Competitive Edge.

2025-10-07Industry Crisis? It's Not a Problem, It's a Catalyst for Strategic Technology Investment.

For many manufacturing companies in Poland, particularly in industrial heartlands like Silesia or Greater Poland, the current market situation is a resilience test. Rising wage pressure, unstable energy prices, and the growing demands of key partners, especially from the German automotive sector, force a deep cost analysis. In these conditions, companies that view modernizing their machine park not as a cost but as a strategic investment in survival and growth are building an advantage that will pay dividends for years. Let's see how targeted technology investments address the most significant challenges.

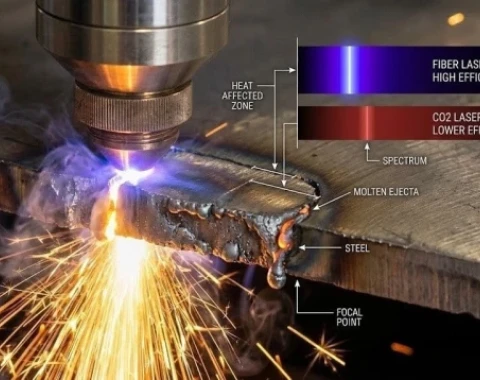

1. Challenge: Soaring Energy Costs and Environmental PressureElectricity prices have become a primary factor affecting production profitability. Older machines, while still operational, often have low energy efficiency. For example, an older CO2 laser can consume over 50 kWh, whereas its modern fiber counterpart with comparable cutting power needs only 15-18 kWh. That's over 70% in energy cost savings for a single device, generating tens of thousands of euros in savings annually.

Technological Solution: Investing in machines with modern drives, such as servo-electric press brakes instead of hydraulic ones, and replacing plasma or CO2 cutters with fiber lasers, is now the most effective way to lower bills and meet rising environmental standards.

2. Challenge: Shortage of Skilled Operators and Wage PressureFinding an experienced CNC operator or welder in the Polish labor market is increasingly difficult and expensive. Relying on the knowledge of a few key, hard-to-replace employees is a huge operational risk. A shortage of labor directly limits production capacity and stifles company growth.

Technological Solution: Automation and robotics are no longer the future; they are the present. A robotic welding station can operate in a three-shift mode with consistent, high quality, and one operator can supervise several machines. Modern CNC control systems are more intuitive, which shortens the training time for new employees and reduces the risk of costly errors.

3. Challenge: High-Quality Requirements and Short Lead TimesCustomers, especially from demanding markets like Germany or Scandinavia, expect perfect repeatability and short delivery times. An outdated machine park is often unable to meet these demands, leading to defects, delays, and the loss of valuable contracts.

Technological Solution: Modern machining centers and laser cutters offer previously unattainable precision (down to 0.05 mm) and speed. Advanced features, like 5-axis machining or active angle correction systems in press brakes, allow for the production of complex components in a single setup, drastically shortening production time and improving quality.

Summary: Investing in Technology is Investing in the FutureCompanies that actively modernize their production facilities don't just reduce costs and solve staffing problems. Above all, they build a foundation for stable growth, becoming less dependent on market fluctuations and opening the door to more profitable, technologically advanced contracts. Now is the best time to analyze your machine park.

Contact the experts at WeSellMachines. We will help you diagnose areas that require modernization and select the technologies that will become the driving force of your company in the competitive European market.

Content added:

Marcin Białczyk

Marcin Białczyk

使用以下方式登录 Facebook

使用以下方式登录 Facebook 使用以下方式登录 Google

使用以下方式登录 Google