Ads Professional CNC and conventional machines for metal processing from Zachodniopomorskie

CNC Lathe Gildemeister NEF 400 (2005 Urgent

Added: 13.10.2025, 13:03

VENUS 200 CNC – Precision Automatic Lathe (2022) Urgent

Added: 13.10.2025, 12:44

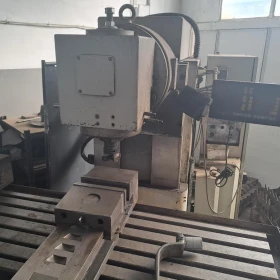

WAGNER VMC 1400 - Ready-to-Work Machining Center Urgent

Added: 13.10.2025, 11:00

Two ITALMEC TBNS/9 Wet Drawing Lines (2022) - Slippage-Free Technology Urgent

Added: 07.10.2025, 12:42

PREBENA High-Speed Eccentric Press 63 Tons - Optimized for Staple and Stamping Production Urgent

Added: 07.10.2025, 11:36

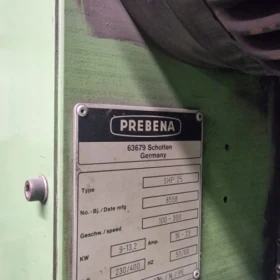

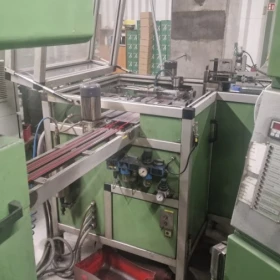

Prebena SHP 25 Staple Production Line Urgent

Added: 07.10.2025, 10:42

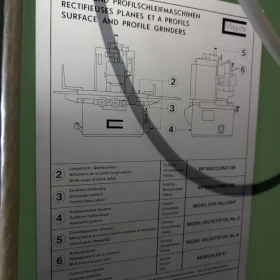

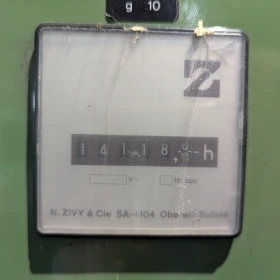

Mägerle F-V-A-SL1 Surface and Profile Grinder (MACCURAT) – Swiss Precision at a Competitive Price Urgent

Added: 02.10.2025, 16:21

Universal Milling Machine WMW Heckert FU450R-51 | Year 2009 | Large Table 1800x450 mm Urgent

Added: 26.09.2025, 14:34

CNC Plasma-Gas Cutting Machine AJAN SHP 260A (2014) – Dual Gantry, High Performance Urgent

Added: 26.09.2025, 13:44

MAKTEK CQ6236G-1/1000 Universal Lathe | 2014 | Multifix Tool Post Urgent

Added: 25.09.2025, 13:02

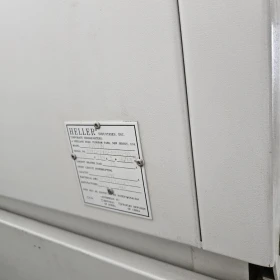

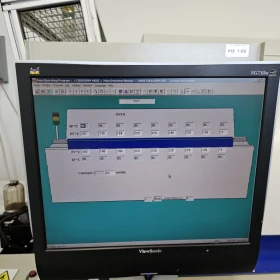

Heller 1809EXL SMT Reflow Oven | 9 Heating Zones | Lead-Free | 2006 Urgent

Added: 25.09.2025, 11:45

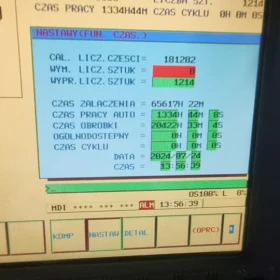

AVIA FNC-25 Toolroom Milling Machine with Digital Readout (DRO) | Year: 1995 Urgent

Added: 24.09.2025, 19:04

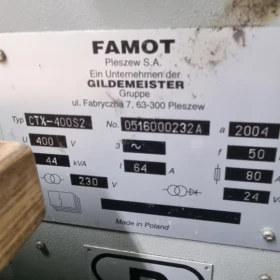

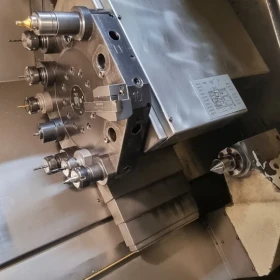

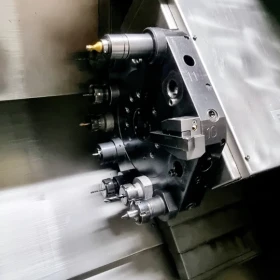

FAMOT CTX-400S2 CNC Lathe (Year of Manufacture 2004) - Functional, Ready for Work!

Added: 04.06.2025, 12:58

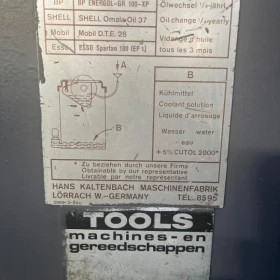

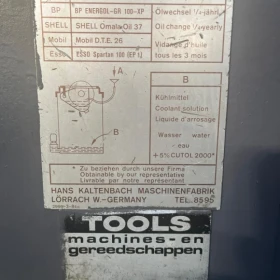

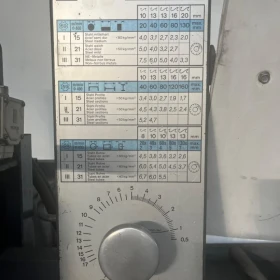

KALTENBACH Cold Saw - Hydropneumatic, Semi-Automatic (Service Required)

Added: 29.05.2025, 12:08

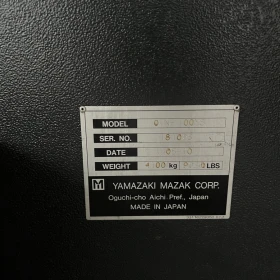

Precision CNC Lathe Mazak Quick Turn Nexus 100MS - 2006 Year Urgent

Added: 04.03.2025, 10:57

Advanced Metal Processing - Used CNC Machines from World Leaders

We specialize in supplying top-class used metal processing machines: 3-5 axis machining centers, CNC lathes, milling machines, grinders, laser and plasma cutters, and EDM machines. Our portfolio includes brands such as DMG Mori, Mazak, Okuma, Haas, Trumpf, and Amada. Each machine undergoes comprehensive diagnostics according to ISO 230 and VDI/DGQ 3441 standards, including tests for geometry, positioning, interpolation, and load. Investing in used CNC machines allows you to save 45-65% while maintaining accuracy of ±0.005mm and reliability at >95% MTBF.

Critical Parameters Verified Before Sale

We perform laser calibration of positioning (accuracy ±0.008mm, repeatability ±0.004mm), ballbar circular interpolation testing (error <0.015mm), measurement of backlash on all axes (<0.005mm), modal analysis of dynamic stiffness (>60Hz first natural frequency), thermography of spindles and servo drives, and bearing vibration analysis (ISO 10816-3). We document volumetric compensations and collision/overload histories.

Key Machines in the Portfolio:

Vertical Machining Centers (VMC): DMG Mori NVX, Mazak VCN, Haas VF. Working areas from 500×400 to 2000×1000mm, spindles 10k-20k RPM, BT40/50 or HSK-A63, tool magazines 30-120 tools.

Horizontal Machining Centers (HMC): Makino A61NX, Okuma MA, DMG DMC. Pallets 400-800mm, indexed or continuous B-axis, critical chip management.

CNC Lathes: Okuma LB, Mazak QTN, DMG CTX. Diameters 200-600mm, lengths up to 1500mm, driven tools, Y-axis, counter-spindle options.

5-Axis Systems: DMG DMU, Hermle C, Mikron HPM. Simultaneous 5-axis, accuracy <0.010mm, RTCP/TCPC, collision avoidance.

Advanced FAQ - Precision Diagnostics and Performance

How to Conduct Full Diagnostics of the Mazak VCN-530C Machining Center According to ISO 10791?

Static geometry test (ISO 10791-1): Flatness of the table: granite ruler + sensor, <0.02mm/1000mm. Perpendicularity of axes: granite square, XY/XZ/YZ <0.015mm/500mm. Parallelism of T-slots: <0.02mm over length. Straightness of guides: laser or ruler, <0.012mm/500mm. Positioning test (ISO 10791-2/ISO 230-2): Setup: Renishaw XL-80 laser, active environmental compensation. Parameters: 5 bi-directional measurements, target points every 50mm. X-axis (1050mm): A≤±0.010mm, R≤±0.005mm, reversal <0.008mm. Y-axis (530mm): A≤±0.008mm, R≤±0.004mm. Z-axis (510mm): A≤±0.008mm, R≤±0.004mm, weight compensation. Backlash: measured <0.005mm, compensated in Mazatrol. Interpolation test (ISO 10791-4/ISO 230-4): Renishaw QC20-W ballbar, radius 150mm, F=1000mm/min. XY plane: roundness <0.015mm, reversal jumps <0.008mm. XZ/YZ plane: roundness <0.018mm (gravity effect). Analysis: perpendicularity <0.010mm, scale mismatch <0.005mm. Servo tuning: if stick-slip >0.003mm, recalibration required. Spindle test 12000RPM (ISO 10791-5): Runout at tool: <0.003mm sensor at 300mm. Thermal drift: <0.02mm after 30min @max RPM. Vibration: <2.5mm/s RMS, accelerometer on the casing. Power: S1 characteristic 22kW continuous verified. Orientation: C-axis ±0.001° at M19. Dynamic stiffness test: Modal hammer test: >60Hz first natural frequency. Compliance: <0.5μm/kN at tool tip (static load test). Damping: >3% for dominant modes. Stability curves: calculation for 4-flute end mill Ø16mm. Cutting tests (ISO 10791-7): Test sample NAS 979: aluminum, 15 features, tolerances ±0.02mm. Surface finish: Ra<1.6μm at ae=0.5×D, fz=0.1mm. Positioning accuracy: hole locations ±0.015mm. Cylindricity: <0.010mm on Ø50mm interpolated hole. Full grooving: no vibration at 0.7×max spindle power. Mazatrol SmoothX control system: All axes base repeatability <0.001mm. Thermal compensation: active, 5 sensors, drift <0.015mm/8h. Tool measurement: laser or probe, accuracy ±0.005mm. Workpiece coordinates: probe calibration <0.005mm sphere. Network: Ethernet response <50ms, MTConnect data streaming. Documentation: Laser calibration certificates for all axes. Ballbar graphs with error analysis. Spindle vibration spectrum up to 10kHz. Cutting test reports with CMM dimensions. Maintenance history: collision log, spindle hours.

How to Optimize Turning Parameters on the Okuma LB3000EX-II Lathe for Stainless Steel 316L?

Tool parameters for 316L (austenitic, 170-220 HB): Insert grade: PVD-TiAlN coated, positive geometry, chip breaker for control. Corner radius: 0.8mm standard, 0.4mm for finishing. Approach angle: 95° CNMG for roughing, 35° DNMG for profiling. Roughing parameters (Ø60mm, depth 3mm): Vc = 120-150 m/min (640-800 RPM for Ø60). Feed = 0.25-0.35 mm/rev (less for work hardening). Depth = 2-3mm (ap), multiple passes better than deep cuts. Coolant: high pressure 70 bar directed chip breaking. Tool life: 15-20 min at continuous cutting. Semi-finishing (depth 0.5-1mm): Vc = 160-180 m/min for better finish. Feed = 0.15-0.20 mm/rev. Fresh edge critical - 316L work hardens. Constant surface speed (CSS) active. Finishing (depth 0.1-0.3mm): Vc = 180-220 m/min maximum for Ra. Feed = 0.05-0.10 mm/rev for Ra<0.8μm. Wiper insert option for Ra<0.4μm. Minimum depth 0.15mm - avoid rubbing. Chip control: Problem: long stringy chips typical for 316L. Solution: high-pressure coolant 70-100 bar through the tool. Chip breaker geometry matched to feed. Feed oscillation (macro G-code) ±20% for breaking. OSP-P300L optimizations: THINC-OSP: real-time thermal compensation active. Collision avoidance: 3D simulation before cycle start. Tool wear compensation: automatic measurement every 20 parts. Adaptive control: load monitoring, overwrite feed 50-120%. Harmonic filtering: vibration damping 200-800Hz. Specific issues for 316L: Work hardening: do not stop feed, continuous motion. Lubrication: use sharper tools, higher speeds. Thermal: compensate for expansion 17μm/m/°C. BUE (Built-Up Edge): Vc>150 m/min prevents. Dimensional accuracy: IT7 tolerance (Ø60h7 = +0/-0.030): Tool wear compensation every 10-15 parts. Thermal compensation: warm-up 20 min, measurement every 30 parts. Statistical process control: target Cpk>1.33. Surface: Ra 0.8μm consistently: fresh edge, stable parameters. Ra 0.4μm: wiper geometry + optimal Vc/f ratio. Ra 0.2μm: super-finishing pass, ceramic tool option. Efficiency: Cycle time for Ø60×200mm shaft: Roughing: 4 min (3mm passes). Semi-finishing: 2 min. Finishing: 1.5 min. Total: 7.5 min + handling. Tool cost: ~2-3€/part for carbide inserts. Productivity: 6-7 parts/h with manual loading.

Log in with Facebook

Log in with Facebook Log in with Google

Log in with Google